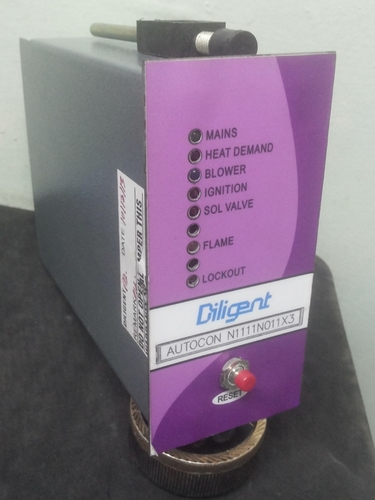

Burner Controller

4500 आईएनआर/टुकड़ा

उत्पाद विवरण:

- साइज Different Available

- रंग Purple And Grey

- उपयोग Industrial

- शर्त नया

- मटेरियल Metal

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- टुकड़ा/टुकड़े

- टुकड़ा/टुकड़े

- 1

उत्पाद की विशेषताएं

- Different Available

- Metal

- Industrial

- Purple And Grey

- नया

व्यापार सूचना

- प्रति सप्ताह

- हफ़्ता

उत्पाद वर्णन

A burner controller is a device used to manage and control the operation of burners in various heating applications, such as industrial furnaces, boilers, ovens, and other combustion systems. The primary purpose of a burner controller is to ensure safe, efficient, and reliable combustion processes.

Key functions of a burner controller include:

1. Ignition Control: The burner controller manages the ignition sequence of the burner. It ensures that the igniter or pilot flame is ignited properly before the main burner flame is established.

2. Flame Monitoring: The controller uses sensors to monitor the presence and stability of the flame. If the flame is detected to be unstable or extinguished, the controller takes appropriate actions to reignite the burner or shut down the fuel supply to prevent unsafe conditions.

3. Fuel and Air Regulation: A burner controller adjusts the flow of fuel and air to achieve the desired combustion ratio. This helps maintain efficient combustion and minimize emissions.

4. Safety Features: Burner controllers include safety features to prevent dangerous situations. These features may include flame failure detection, high-temperature shutdown, and overpressure protection.

5. Modulation Control: In many applications, burners need to adjust their output to meet changing heating demands. Burner controllers can modulate the fuel and air supply to achieve different levels of heat output.

6. Remote Monitoring and Control: Advanced burner controllers might offer remote monitoring and control capabilities. This allows operators to monitor burner performance and make adjustments remotely, improving operational efficiency.

7. Diagnostic and Reporting: Some burner controllers provide diagnostic information and reports about the burner's performance, helping maintenance personnel identify issues and optimize the system.

8. Integration: Burner controllers can be integrated into larger control systems, such as building management systems or industrial automation systems.

FAQ:

Q. What is a burner controller?

Ans: A burner controller is a device used to manage and control the operation of burners in various combustion systems, such as industrial furnaces, boilers, and ovens. Its primary purpose is to ensure safe, efficient, and reliable combustion processes.

Q. What functions does a burner controller perform?

Ans: A burner controller performs functions such as ignition control, flame monitoring, fuel and air regulation, safety features implementation, modulation control for varying heat demands, remote monitoring and control, and diagnostic reporting.

Q. Why is flame monitoring important in burner controllers?

Ans: Flame monitoring ensures the presence and stability of the burner flame. If the flame becomes unstable or extinguished, the controller takes corrective actions to prevent unsafe conditions, such as shutting down the fuel supply.

Q. What safety features are commonly found in burner controllers?

Ans: Common safety features include flame failure detection, high-temperature shutdown, overpressure protection, and emergency shutdown capabilities to prevent accidents and hazardous situations.

Q. How do burner controllers regulate fuel and air?

Ans: Burner controllers regulate the flow of fuel and air to achieve the optimal combustion ratio, ensuring efficient and clean burning. This helps maximize energy efficiency and minimize emissions.

Q. What is modulation control in burner controllers?

Ans: Modulation control allows burners to adjust their heat output according to changing heating demands. Burner controllers modulate the fuel and air supply to achieve different levels of heat output, improving efficiency and reducing energy consumption.

Q. Can burner controllers be monitored and controlled remotely?

Ans: Yes, many advanced burner controllers offer remote monitoring and control capabilities. This allows operators to oversee burner performance, make adjustments, and troubleshoot issues from a remote location, enhancing operational efficiency.

Q. How do diagnostic and reporting features benefit burner controllers?

Ans: Diagnostic and reporting features provide information about burner performance and potential issues. Maintenance personnel can use this data to identify problems, perform preventive maintenance, and optimize system performance.

Q. Are burner controllers integrated into larger control systems?

Ans: Yes, burner controllers can be integrated into larger control systems, such as building management systems or industrial automation systems. This integration allows for centralized control and coordination of various processes.

Q. What are the benefits of using burner controllers?

Ans: Using burner controllers leads to safer operation, improved energy efficiency, reduced emissions, better heat output control, and longer equipment lifespan. They also aid in complying with safety and environmental regulations.

Q. How do I choose the right burner controller for my application?

Ans: Choosing the right burner controller depends on factors such as the type of combustion system, required safety features, modulation capabilities, remote control needs, and integration possibilities. Consulting with experts in combustion systems can help you make an informed decision.

Q. What maintenance is required for burner controllers?

Ans: Regular maintenance includes checking sensor accuracy, cleaning components, verifying safety features, and updating firmware if applicable. Maintenance schedules may vary based on the specific system and usage.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email